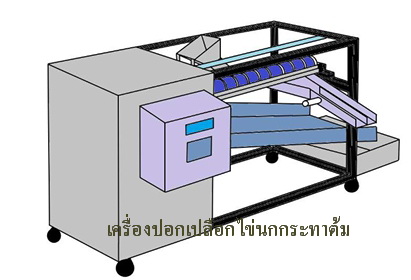

Boiled Quail Egg Peeling Machine

Keywords:

Boiled Quail Egg Peeling Machine, Microcontroller System, Electric Motor SpeedAbstract

This research focuses on the design and development of a boiled quail egg peeling machine, as well as testing its performance. The objective is to address the labor-intensive process of peeling quail eggs by creating a machine that ensures cleanliness, aesthetic quality, and prevents eggs from breaking or being crushed. The tools used in the research include a water pump for rinsing the eggs, caster wheels for easy mobility, and an Arduino microcontroller board. The performance evaluation of the boiled quail egg peeling machine revealed average peeling accuracies of 58%, 54%, 43%, and 40% for peeling 100, 50, 30, and 10 eggs, respectively, with corresponding peeling times of 25, 12, 7.5, and 2.5 minutes. Comparatively, the results demonstrated that the developed machine is significantly faster than manual labor for peeling boiled quail eggs.

References

Emre, Arslan., et al. (2023). Egg weight estimation and the effect of age and plumage colors on some egg quality traits in Japanese quails (Coturnix coturnix japonica). Emirates Journal of Food and Agriculture, 35(6). 569-576.

JH, Salih., AM, Hassan., S., Hussen. (2023). A study of egg quality characteristics for two Asiatic (Coturnix japonica) and two European (Coturnix coturnix) quail lines. IOP Conf. Series: Earth and Environmental Science, 1252(012139).

Camila, Alves, Moreira., et al. (2022). Characterization of quail egg powders obtained by liquid egg drying and foam-mat drying. Journal of the Science of Food and Agriculture, 103(4). 1810-1820.

R, Polat., et al. (2007). Mechanical behaviour under compression loading and some physical parameters of Japanese quail (Coturnix coturnix japonica) eggs. Czech Journal of Animal Science, 52(2). 50-56.

Fredi, Andria., E., Mulyati, Effendi., Aries, Maesya. (2017). Otomatisasi mesin tetas telur puyuh untuk optimasi pembibitan, peningkatan produksi dan pemasaran bagi peternak puyuh. Qardhul Hasan: Media Pengabdian kepada Masyarakat, 3(2). 107-121.

Jaqueline, de, Oliveira, Castro., et al. (2012). Estimate of the weight of japanese quail eggs through fuzzy sets theory. Ciência e Agrotecnologia, 36(1). 108-116.